Thermal Recuperative Oxidizer

The basic design concept of thermal oxidation is to promote a chemical reaction of the air pollutant with oxygen at elevated temperatures. This reaction destroys the VOC emission in the air stream by converting it to CO2, H2O and heat. The rate of reaction is controlled by the factors of time, temperature and turbulence. Air pollutant destruction efficiencies of 99%+ can typically be guaranteed.

Recuperative Thermal Oxidizer Video

Recuperative Thermal Oxidizer – Typical Applications

Common uses include:

- Adhesive coating

- Chemical processing

- Converting web dryers

- Engine test facilities

- Ethanol production

- Heat-set printing

- Metal decorating

- Pharmaceutical manufacturing

- Textile manufacturing

- Many others…

- 4,250 to 51,000+ NCMH

- (2,500 to 30,000+ SCFM)

- (2,500 to 30,000+ SCFM)

- Suited for air streams with moderate to high levels of air pollutant

Recuperative Thermal Oxidizer – Advantages & Disadvantages

Advantages:

- Moderate capital cost

- Low operating costs with moderate to high air pollutant concentrations

- Ease of operation

- Ease of install

Disadvantages:

- High operating costs with low air pollutant concentrations

- Shell-and-tube heat exchanger has long life

expectancy only with continuous operation

Recuperative Thermal Oxidizer – Standard Features by CMM

- High air pollutant destruction efficiencies are guaranteed

- Lowest operating costs available with energy efficient thermal oxidizer design

- Designed to meet your specific project requirements

- Proven high quality components are used throughout

- Control scheme is designed to automatically react to your manufacturing process

- Modern PLC based controls with color touch-screen interface

- Data-logger is included for recordkeeping

- Meets or exceeds all regulations

Request a Quote for Recuperative Thermal Oxidizers

Let us know how The CMM Group can assist you.

REQUEST A QUOTEHow Does a Recuperative Thermal Oxidizer Work?

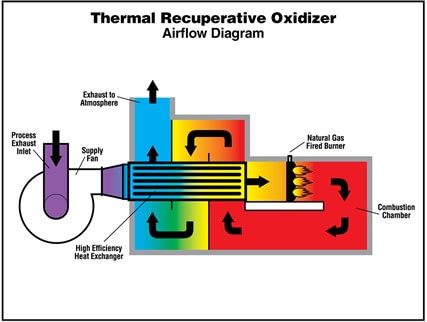

In operation, the process exhaust fumes are forced into the recuperative oxidizer inlet manifold (with a high pressure supply fan) and directed into the cold (tube) side of a high efficiency, stainless steel, multi-pass shell-and-tube type heat exchanger. The pollutant laden air passes through the combustion chamber, is thoroughly mixed for temperature uniformity (turbulence) and held at the elevated set-point temperature (temperature) for a residence time of 0.5 to 1.0 seconds (time). VOC/HAP emission control takes place within the combustion chamber where auxiliary fuel is introduced if necessary.

Recuperative Thermal Oxidizer Efficiency

After passing through the combustion chamber, the clean (hot) air is routed back through the hot (shell) side of the heat exchanger where it continuously preheats the incoming air. Upon exiting the heat exchanger, the clean (cooled) air is routed through an exhaust chamber and ultimately through the exhaust stack. Heat exchangers for use in standard thermal recuperative units are typically fabricated from heavy duty stainless steel. Thermal efficiencies range from 40% to 80% with expansion joints as required. To maintain low external shell temperatures and minimize radiant heat loss, the unit is internally insulated with long-life ceramic fiber modules. The external shell is made of carbon steel.

Recuperative Thermal Oxidizer Service

The CMM Group offers expert thermal oxidizer services for projects of all sizes. We offer services for new and existing equipment, including:

- RTO Rebuilds & Upgrades: improve equipment performance and productivity

- RTO Maintenance: minimize downtime and maximize efficiency with our preventative services

- RTO Installation & Relocation: from contractor supervision to turnkey installation

- Technical Services: consulting, site engineering, manufacturing, turnkey installation

- Permanent Total Enclosures: increase VOC concentration to your thermal oxidizer

VOC Recovery Systems: Request a Quote

Contact The CMM Group with questions or request a quote and let us know how we can assist you or provide more information on our VOC destruction systems.

REQUEST A QUOTE

What CMM Customers Say

“The hard work and dedication your team made this project a great success. I greatly appreciate that the installation went exactly as planned both time and budget wise, and that we were back in production with minimal disruption as promised. Additionally the efficiencies and energy savings have proven to be accurate and genuine.”-Satisfied customer,