Manufacturing plants that generate a low to moderate amount of pollutants can reduce operating costs by using a rotary concentrator for VOC and air pollutant abatement.

How a Rotary Concentrator Works

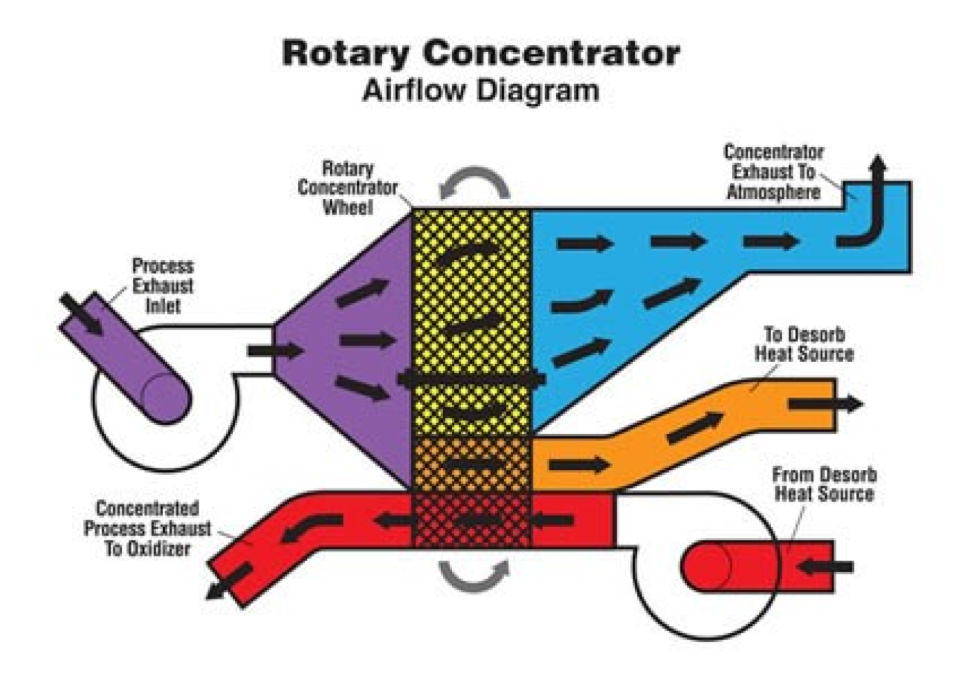

A rotary concentrator efficiently removes and destroys volatile organic compounds (VOCs) and air pollutants with a two-step process.

A ductwork collection system in a rotary concentrator captures exhaust air, which is then passed through a high-efficiency filter to remove particulates.

Next, the airstream is directed through the rotating concentrator wheel, where pollutants are adsorbed by the hydrophobic Zeolite media, which is permanently bonded to a corrugated mineral fiber substrate inside the rotor.

The pollutants are then removed from the Zeolite media and destroyed by an oxidizer. Approximately 90% of the clean air is routed to the exhaust stack while the remainder goes through a cooling plenum.

The Pros and Cons of a Rotary Concentrator

Rotary concentrators offer the following benefits:

- Low operating costs.

- High efficiency at low concentrations.

- Cost efficiency in high-volume, low-capacity applications.

- Zeolite is non-flammable, inert, and high temperature resistant.

You should also consider these potential limitations:

- High capital costs.

- Destruction efficiency of VOC/HAP air pollutant is around 96%.

- Limited to low inlet temperatures.

- The many moving parts require more maintenance.

This air pollution abatement method is most suitable for industries such as chemical processing, automotive, steel/wood furniture paint booths, printing, beverage can manufacturing, semiconductor fabrication, LCD panel manufacturing, and composite manufacturing.

How to Optimize the Efficiency of Your Rotary Concentrator

A rotary concentrator’s efficiency is affected by a variety of factors, including the exhaust temperature, humidity, and the velocity at which the airstream passes through the zeolite media. As such, the environment in which the abatement process takes place should be closely monitored for optimal performance.

Because the equipment’s efficiency depends on the zeolite’s ability to absorb pollutants from the airstream, it’s vital to monitor the media’s effectiveness.

Regular equipment inspection and maintenance is also critical due to the many moving parts in a rotary concentrator. It helps ensure that the exhaust airstream is directed through the equipment at an optimal speed to remove as many pollutants as possible.

In addition, ensure that the thermal oxidizer is functioning optimally by implementing a comprehensive maintenance plan:

- Collect data and use predictive analytics to measure temperature profiles and identify areas that need repair.

- Find and repair any cracks between the structured blocks and the insulation as soon as they appear.

- Conduct weekly inspections of the oxidizer’s exterior to look for signs of insulation failures such as heat marks, warped steel, damaged fasteners, and discolorations.

- Regularly inspect switching valves to identify excessive wear and tear or alignment issues.

Final Thoughts

The rotary concentrator can be a very cost-efficient solution for air pollution abatement. It’s important to make sure the technology is the right fit for your industry and the emission level of your manufacturing facility.

In addition, working with a reputable vendor can help you install the equipment properly and perform ongoing maintenance to optimize the performance of this essential piece of VOC abatement equipment.