It’s no secret that certain types of factories can release dangerous pollutants into our atmosphere. Paint manufacturing plants, for instance, can produce dangerous byproducts in the form of vapor or gas emissions, which are known as volatile organic compounds or VOCs.

This has led to the development of emission control equipment and strategies that destroy VOCs, while only producing heat, water, and carbon dioxide as byproducts. One of the most popular and effective systems out there are Regenerative Thermal Oxidizers, also known as RTOs.

In this article we will discuss the hazards of VOCs, the regulations that paint manufacturing plants must follow, and why RTOs are one of the most effective ways to control dangerous emissions.

Source: Shutterstock

What are VOC Emissions?

As we mentioned before, VOC emissions are dangerous organic compounds that come as a byproduct of industrial processes, such as paint manufacturing. Because they are one of the integral elements commonly used by paint manufacturing equipment, VOC concentrations and emissions tend to be extremely high for these factories.

Excessive exposure can result in throat and eye irritation, respiratory complications, headaches and loss of coordination, allergic reactions, epistaxis, and declines in serum cholinesterase, as well as the production of carcinogens in both humans and animals.

Although there are paint manufacturing processes that reduce the amount of VOC present in paint, destroying emissions from a factory can be extremely different. CMM has developed emission control systems such as RTOs, that provide air pollutant destruction efficiencies exceeding regional, state, and national standards.

EPA Requirements and Regulations

As a result of the Clean Air Act (CAA), the Environmental Protection Agency, or EPA, is in charge of regulating VOC emissions. Known as the National Ambient Air Quality Standards (NAAQS), they set an acceptable volatile organic compound emission and pollution control standards for paint manufacturers across the country.

Moreover, states have the responsibility of developing a general blueprint to reach and maintain the NAAQS in all parts of the country. But what does this mean for paint manufacturing plants?

In a nutshell, paint factories have to find a way to treat or destroy the pollutants they emit before releasing their byproducts into the atmosphere. This is where Regenerative Thermal Oxidizers come into play.

Source: Shutterstock

Regenerative Thermal Oxidizers

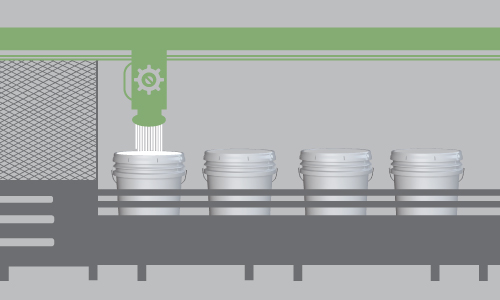

There are a few options when it comes to treating or destroying VOCs, but Regenerative Thermal Oxidizers may be the most appealing for paint factories. As the name suggests, RTOs destroy VOCs and other harmful emissions by using high temperatures that range from 1,500F° (815°C) to 1,800°F (980°C), only producing water, gas, and heat as byproducts.

The reason why these pieces of emission control equipment provide an attractive alternative for paint factories is they have a high VOC destruction rate while keeping extremely high levels of thermal efficiency. Paint factories are notorious for producing alarming amounts of VOC, so having a reliable emission control system that helps abide by EPA regulations while having low operating costs is of critical importance.

In Conclusion…

Although extensive exposure to VOC can result in severe health conditions, paint manufacturers are required to treat these dangerous chemicals before they are released into the air. Thanks to efficient emission control strategies like RTOs, these companies can start implementing cost-effective solutions that end up cutting operating costs in the long run.

If you are interested in learning more, get in touch with us today and find out how our emissions control equipment can help your paint factory today.