The Environmental Protection Agency (EPA) classifies a Volatile Organic Compound (VOC) as “any compound of carbon that participates in atmospheric photochemical reactions.” This classification excludes carbon monoxide, carbon dioxide, carbonic acid, ammonium carbonate, metallic carbides, and carbonates. VOCs are released into the air when harmful chemicals vaporize. The boiling point of a particular compound can be used to gauge how easily it vaporizes, and therefore how volatile it is. The lower the boiling point, the higher the volatility.

The EPA monitors the amount of VOCs released into the air by manufacturing plants and sets restrictions on their annual emissions. By understanding which type of VOC is being released throughout the production cycle, manufacturers can choose the right emission control system for their particular plant.

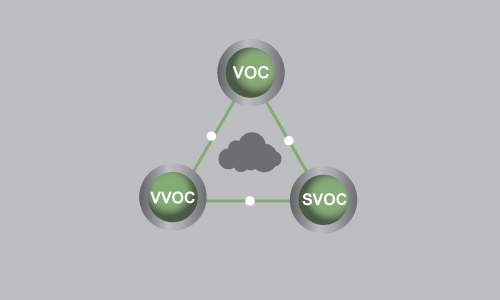

Types of VOCs

The EPA categorizes VOCs by their volatility. While the compounds in each category are still considered harmful, their varying boiling points affect how easily they can be absorbed into the air. The EPA recently changed the labeling of harmful outdoor emissions from Reactive Organic Compounds (ROGs) to VOCs.

However, VOC emission limits do not only apply to outdoor vapors. The quality of indoor environments must also be carefully monitored by manufacturers. The same VVOCs, VOCs, or SVOCs must be captured and destroyed to protect the health of plant employees. Regardless of the environment, manufacturers must know what type of VOC is being emitted, where the pollutants are being deposited, and how many VOCs are being released.

Very Volatile Organic Compounds (VVOC)

VVOCs have a boiling point range of <0 to 50-100 degrees centigrade. Due to their high volatility, these compounds often exist solely as a gas. Manufacturers using chemicals and solvents that produce VVOCs must be equipped to capture and dispose of these emissions with great efficiency. The following compounds are examples of VVOCs:

- Propane

- Butane

- Methyl Chloride

Volatile Organic Compounds (VOC)

VOCs have a boiling point range of 50-100 to 240-260 degrees centigrade. Although this term is often attributed to all volatile compounds, only the ones that vaporize at these temperatures are considered VOCs. The following chemicals are examples of standard volatile organic compounds:

- Formaldehyde

- D-Limonene

- Toluene

- Acetone

- Ethanol (Ethyl Alcohol)

- 2-propanol (Isopropyl Alcohol)

- Hexanal

Semi-Volatile Organic Compounds (SVOC)

SVOCs have a boiling point range of 240-260 to 380-400 degrees centigrade. Although these chemicals are less volatile, it does not mean they can not—or should not—be captured and destroyed. The following are all examples of SVOCs:

- Pesticides (DDT, Chlordane, Plasticizers (Phthalates)

- Fire retardants (PCBs, PBB)

When selecting the right pollution control equipment, manufacturers must take into account the type of VOC being released. For example, a plant with higher levels of VVOCs may have an increased concentration of pollutants in the air. This is due to the fact that VVOCs vaporize at lower temperatures. In this case, a Regenerative Thermal Oxidizer (RTO) may be the right choice as these units work best with moderate to high concentrations of air pollution.

In contrast, plants that release SVOCs may have lower concentrations of air pollution due to the higher boiling points required for the compounds to vaporize. Therefore, a Recuperative Thermal Oxidizer (TO) may be better suited as these units work well with lower concentrations.