For many industrial manufacturers, choosing a VOC abatement technology can have a significant impact on their operating cost and therefore, profitability.

You need to consider the many facets of an emissions control solution – such as upfront investment, ongoing maintenance, the total cost of ownership, energy usage, and plant design – to select the most cost-effective solution for your facility.

A Regenerative Thermal Oxidizer (RTO) is a VOC abatement technology that works well for many manufacturing plants. Here’s what you need to know when choosing your emissions control solution:

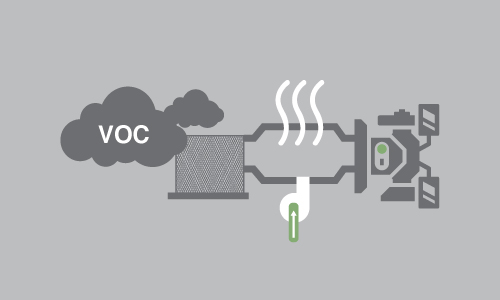

How Does a Regenerative Thermal Oxidizer (RTO) Work?

The process of VOC abatement in an RTO is divided into two phases:

Pollutant Destruction Phase

Pollutant-laden exhaust fumes are forced by a high-pressure supply fan into one of the energy recovery canisters in the RTO. The exhaust air then travels through the first heat exchanger canister, where it absorbs heat from the ceramic media.

The preheated air is directed into the combustion chamber, in which the high temperature causes oxidation to occur and destroys the pollutants.

The Clean Air Cycle

The clean, hot air is then directed from the combustion chamber into a second energy recovery canister, in which the ceramic media absorb the heat generated during thermal oxidation. The heat can be reused in the pollutant destruction phase or in other parts of the plant (e.g., for heating) to improve energy efficiency.

The cooled, clean air is finally routed through outlet switch valves and the exhaust stack and released into the atmosphere.

The Benefits of Using an RTO for Emissions Control

There are numerous reasons why an RTO is a cost-effective VOC abatement solution for many manufacturing plants:

- High thermal energy efficiencies, ranging from 85% to 97%.

- Typical destruction efficiencies of 99%+ on VOC and other air pollutants.

- Low operating cost, partly thanks to its heat recovery mechanisms.

- Versatile application and high durability, making it a great option for many industries.

- Simple design and easy maintenance – a team member can perform day-to-day upkeep with some basic training from the manufacturer.

- When used for VOCs with high energy content, you can further lower the energy requirements and associated operating costs.

Considerations When Using RTO for VOC Abatement

There are a few things you should take into account when considering an RTO for emissions control:

- The installation may require a larger real estate footprint.

- The combustion process could generate nitrogen oxides, a pollutant that needs to be controlled.

Selecting an RTO Solution for Your Manufacturing Plant

For most manufacturers, the benefits of using RTOs for emissions control far outweigh the disadvantages.

However, not all RTOs are created equal. With proper design, construction, and installation by a reputable manufacturer, you can increase the efficiency and lower the operating costs while mitigating many of the potential downsides with a modern RTO solution.

Learn more about our custom-designed RTO and VOC abatement technology here.